Bored Well Construction

Bored wells are drilled using a rig mounted, large diameter bucket auger. Once the borehole is completed large diameter cement tiles are installed in the borehole. These tiles are typically 3 feet in length, which means that there is an open joint about every three feet the length of the well. If constructed properly the top 10 feet should be grouted, which should seal the upper tile joints.

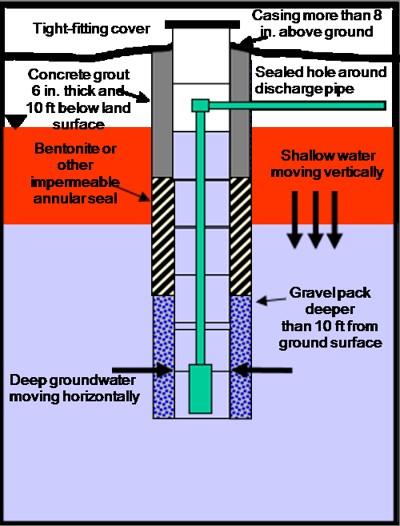

Diagram above is of a properly constructed bored well. Diagram not to scale.

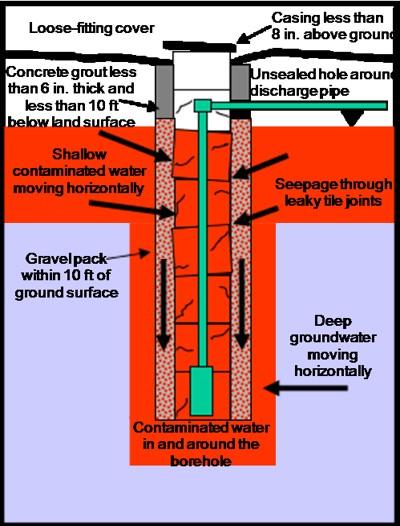

Diagram above is of an improperly constructed bored well. Diagram not to scale.

Improperly constructed bored wells allow potentially contaminated surface and near surface water to enter the well and potentially contaminate the local groundwater.

In Kentucky, most bored wells are equipped with a submersible pump, which has a discharge pipe that runs through the cement tile casing to the pressure tank. In order to plumb the discharge pipe through the tile casing the certified well drill has to knock a hole in the side of the tile casing. If the discharge pipe hole is not properly sealed, like in the above picture, surface water can enter the well and potentially contaminate the drinking water source.

Improper Bored Well Head Construction

Proper Bored Well Head Construction